Choosing the Right Rivet Length for Your Design

TL:DR – Grip length = thickness of joint. Solid Rivet Length = thickness of joint + material needed for full head.

Choosing the correct rivet length for structural and nonstructural purposes is important for making full use of the material properties of the chosen rivet. Rivets are permanent mechanical fasteners that plastically deform to maintain axial loading on a joint. The most common rivets used are:

Blind Rivets: A tubular rivet with a mandrel in the center. These rivets are installed by pulling the mandrel from the rivet ‘head’ end, deforming the opposite side. The mandrel is ultimately broken off, flush with the rivet head.

Solid Rivets: A solid metal shaft with a rivet ‘head’ on one end. Solid rivets are installed by securing the rivet ‘head’, while hammering the opposite side to plastically deform, or by use of an air powered or other mechanical rivet compression tool that will secure the ‘head’ and compress the rivet shaft at the same time.

Flush and Round Head Rivets: Both blind rivets and solid rivets can have a flat/countersunk head as well as a round head. The flush head rivets are commonly countersunk at 82 degrees and 100 degrees and are installed into a countersunk hole. Round head rivets are more traditional, leaving a smooth round fastener head visible after installation.

Rivet Dimensions

Whether for a commercial application or military application, it is beneficial to look at the military specification sheets for the general rivet category you are considering using. The specification sheet will provide an understanding of the installation requirements (or recommendations) for a rivet class based on the material, length, head shape, and other factors.

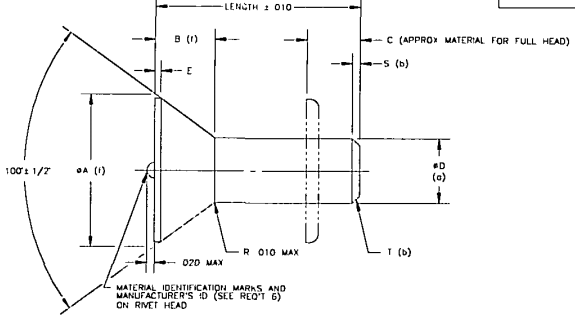

Figure 2: Dimensional diagram of a flush head solid rivet. Taken from MS20426L Military Specification Sheet Rivet, Solid, Countersunk 100 deg, Precision Head, Aluminum and Titanium Columbium Alloy (for reference).

Figure 2: Dimensional diagram of a flush head solid rivet. Taken from MS20426L Military Specification Sheet Rivet, Solid, Countersunk 100 deg, Precision Head, Aluminum and Titanium Columbium Alloy (for reference).

If you are a designer or a manufacturer, you have probably seen a rivet callout on a drawing with a dash number called “optional” or “optl” or some other variation. This is generally done in a nonstructural design decision and leaves the rivet length choice up to the manufacturing or production personnel.

The flush head blind rivet shown in figure 1 shows a “GRIP” dimensional length, whereas the flush head solid rivet shown in figure 2 shows a “C (APPROX MATERIAL FOR FULL HEAD)” dimensional length.

How to Interpret

When determining the required length of a rivet, first measure the thickness of the joint being riveted. Keep in mind the thickness tolerance of the joint being considered.

Figure 3: Dimensional table for passivated stainless steel alloy sleeve and stem (mandrel) referencing figure 1 variables. Taken from MS20605N Military Specification Sheet Rivet, Blind, Nonstructural, 100 deg Flush Head, Class 2 (for reference).

The grip dimensional length is generally a range, and dictates the minimum and maximum joint thicknesses the specific rivet can be used with while keeping intended structural integrity. If your joint is close the maximum or minimum of the range, use the thickness tolerances to determine if your rivet should be longer or shorter. For round head rivets, use the flat base of the head to determine length of the rivet (functional length). See figure 3 for what a grip range may look like for reference.

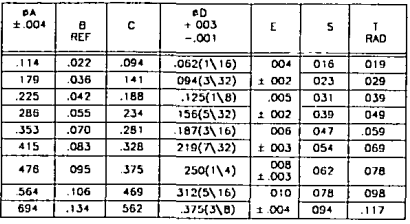

Figure 4: Dimensional table referencing figure 2 variables. Taken from MS20426L Military Specification Sheet Rivet, Solid, Countersunk 100 deg, Precision Head, Aluminum and Titanium Columbium Alloy (for reference).

The length of a solid rivet can be determined by taking the joint thickness and adding the full head dimensional length requirement based on the rivet diameter being used. For example, if you have a joint thickness of 1/4” and you are using a rivet of diameter 3/32”, according to the table on figure 4, your rivet length must be approximately 1/4" + 0.141”, requiring a rivet length of either .375” or .4375”.

Jarrett Linowes

Mechanical Engineer

omniamfg@gmail.com

Did I miss anything you are interested in? Send me an email or comment below!